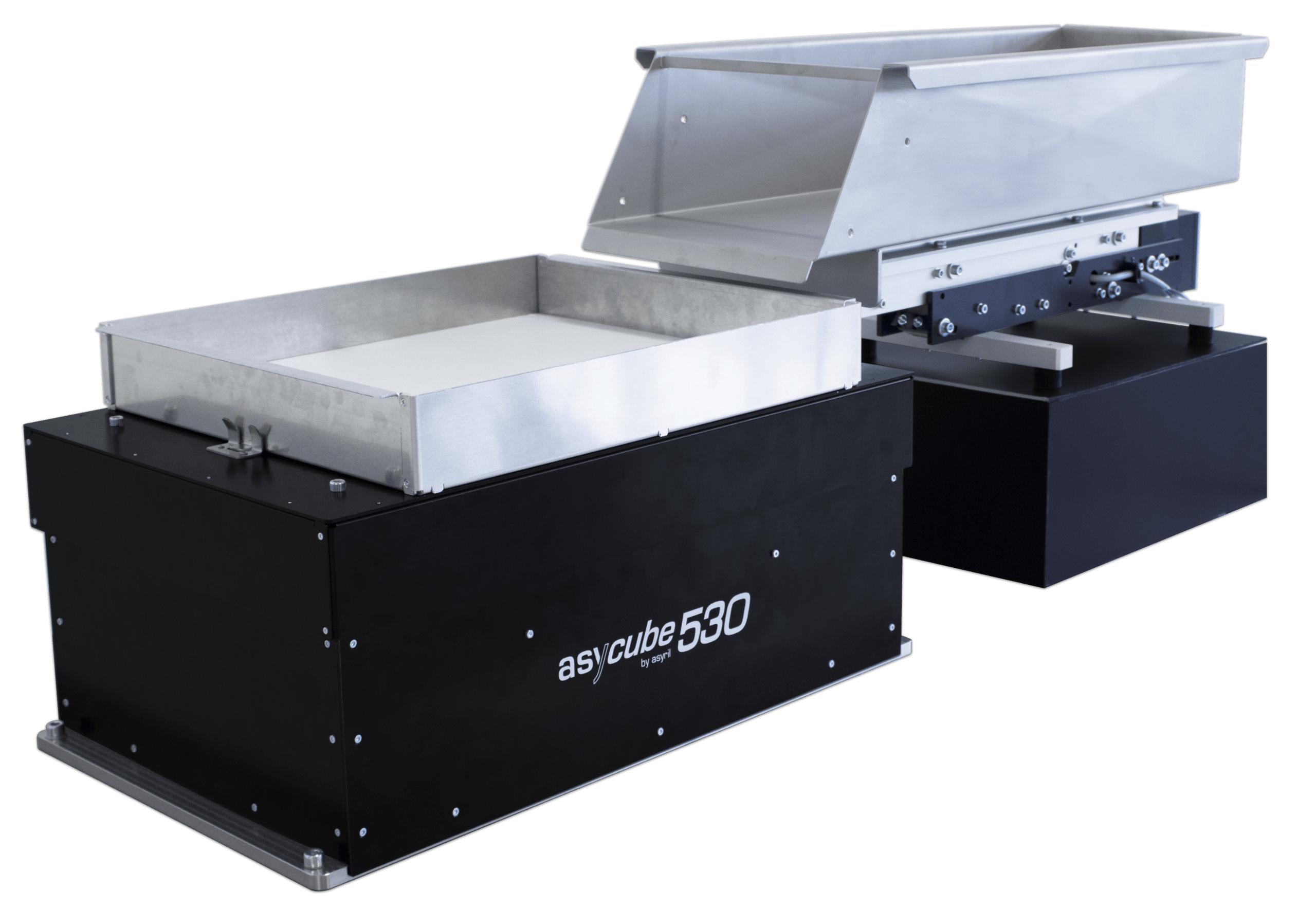

The Asycube 530 is the largest flex feeder in the Asycube range from Asyril. By combining vision technology with 3-axis vibration technology, the 530 is perfect for feeding parts to robots. The flex feeder consists of a conveyor belt that places parts in a bin. The bucket is equipped with a vibratory plate so that parts are evenly distributed over the surface. By distributing the parts evenly, it is always possible for a robot to pick them up in the right way. Vision technology also helps to tell the robot where the objects are. If objects are not properly positioned in front of the robot, the vision sends a signal to the flex feeder and it will move the parts by means of the vibratory plate. It is also possible to place a structured plate on the bottom of the feeder so that the products can fall into a kind of mould. The Asycube 530 is suitable for objects from 30 to 150 mm.

Asyril is a developer and producer of high quality flex feeders. With a unique 3-axis vibration technology and intelligent vision system it is possible to supply a complete range of parts to a robot. The Asycube 50, Asycube 80, Asycube 240, Asycube 380 and Asycube 530 can handle parts from 0.1 to 150 mm.

Datasheet (Asycube-530_ENG.pdf)

Datasheet (Asycube-530_ENG.pdf)