The FMCG world never stops. Higher volumes, more variation, and always that pressure to keep running with too few people. At many companies, you see the same picture: lines that actually run fine, but where the bottlenecks are always the same. And where operators complain about back pain, monotony, and stress during peak times.

Cobots can help with that. Not everywhere, and not always spectacularly, but in a handful of places in your line they can really make quick impact. Below are the five use cases where success is most often achieved in practice.

1. Case packing at the end of the line

You'd think the end of the line would be automated everywhere by now, but nothing could be further from the truth. At many companies, there are still people stacking products into boxes. Same movement all day, sometimes above shoulder height, and when it gets busy, things go wrong.

A cobot can handle this just fine. Pick-and-place with a vacuum gripper or a simple claw, and you've got consistent quality. No more crooked stacks, no damaged products. And operators can be deployed for work where they're really needed.

The nice thing is that case packing is usually straightforward: fixed points, predictable pace, clear task. That makes implementation relatively simple and payback quick.

2. Palletizing

Palletizing is the classic, and for good reason. It's heavy work that nobody wants to do all day. Especially not when you're running multiple SKUs in a shift and your stacking patterns are constantly changing.

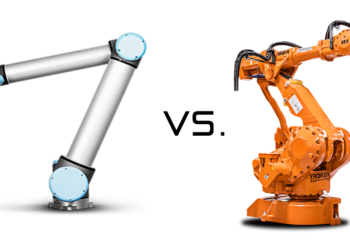

Cobots are a bit slower than large industrial robots, but for FMCG that's usually not a problem. You rarely need truly non-stop top speed. What you do need is flexibility: different boxes, different pallets, promotional setups. And that's where cobots excel.

There are companies that can handle seasonal peaks this way without hiring extra people. And operators who used to go home exhausted in the evening can now move on to other tasks.

A tip: cobot palletizing works best at medium volumes with variation. Running the same box 24/7 at full speed? Then a traditional robot is probably better. But for most FMCG lines, a cobot is exactly the sweet spot.

3. Label checking and visual quality control

FMCG is all about presentation. A crooked label, an unreadable batch code, or the wrong sleeve can cost you dearly. Those checks are usually done by people, but that's hard to maintain. At 3 PM you're still sharp, at 10 PM you don't see it anymore.

A cobot with a vision camera always sees the same thing. It checks every product, compares it to the standard, and automatically sorts out what's not right. You can combine that with spot checks by operators, but the basic check is secured.

This gives not only less scrap and rework, but also a lot of peace of mind towards customers and auditors. It's demonstrable that 100% is being checked, not just "as well as possible."

4. Tray loading for flowpackers and cartoners

Packaging machines need a stable supply. If you have to manually place products in trays or carriers, that quickly becomes a bottleneck. Especially with difficult products: soft packaging, variable shapes, light products that don't sit right.

A cobot can keep doing this constantly and with the same precision. With vision, it can even correct if a product is slightly crooked. And with a product changeover, you just load a new recipe instead of rebuilding half the machine.

The result? The machine runs more constantly, there are fewer micro-stops, and OEE goes up. And with recipe changes, you're done much faster.

5. Repackaging and rework

This is the hidden money leak. Rework: damaged trays, incorrectly packaged products, promotional campaigns where you temporarily have to make bundles. It's messy, often unplanned, and it costs loads of time.

Cobots are perfect for this kind of semi-structured work. They can be deployed as extra hands for temporary jobs, without having to tear apart your entire line. Putting products back in trays, assembling 2+1 promotions, checking boxes and repackaging.

The advantage is that rework no longer comes at the expense of primary production. The cobot keeps running nicely in a corner, and the floor stays tidy.

How do you choose the best spot?

A few simple questions help:

- Is the task the same every day?

- Is the pace reasonably predictable?

- Does it not really require thinking?

- Does it go wrong if it's done wrong (quality/safety)?

- Does it take a lot of time to train people for this?

Three or more times "yes"? Then you probably have a good use case.

Where do you start?

Start small. Choose one clear task, do a pilot, and learn from what works and what doesn't. FMCG rewards pragmatism: not planning for months, but just starting and continuing to develop.

The five spots above are where the fastest results are seen in practice. No rocket science, just smart automation in the right place. And that delivers returns, often faster than expected.

WiredWorkers specializes in integrating cobot systems and has already completed great projects with palletizers. Want to learn more about how collaborative robots can improve your production process? Contact us or schedule a free cobot consultation.