The past year has been an eventful one for many manufacturing companies. In the United Kingdom, for example, the sector recorded its worst figures since the 1980s. At the same time, the manufacturing sector is experiencing a global labor shortage with some 74,000 job openings, which again makes it difficult to scale up. In this blog, we discuss the expectations for 2024 and some of the trends in automation that are increasingly evident later.

Automation is the key to productivity

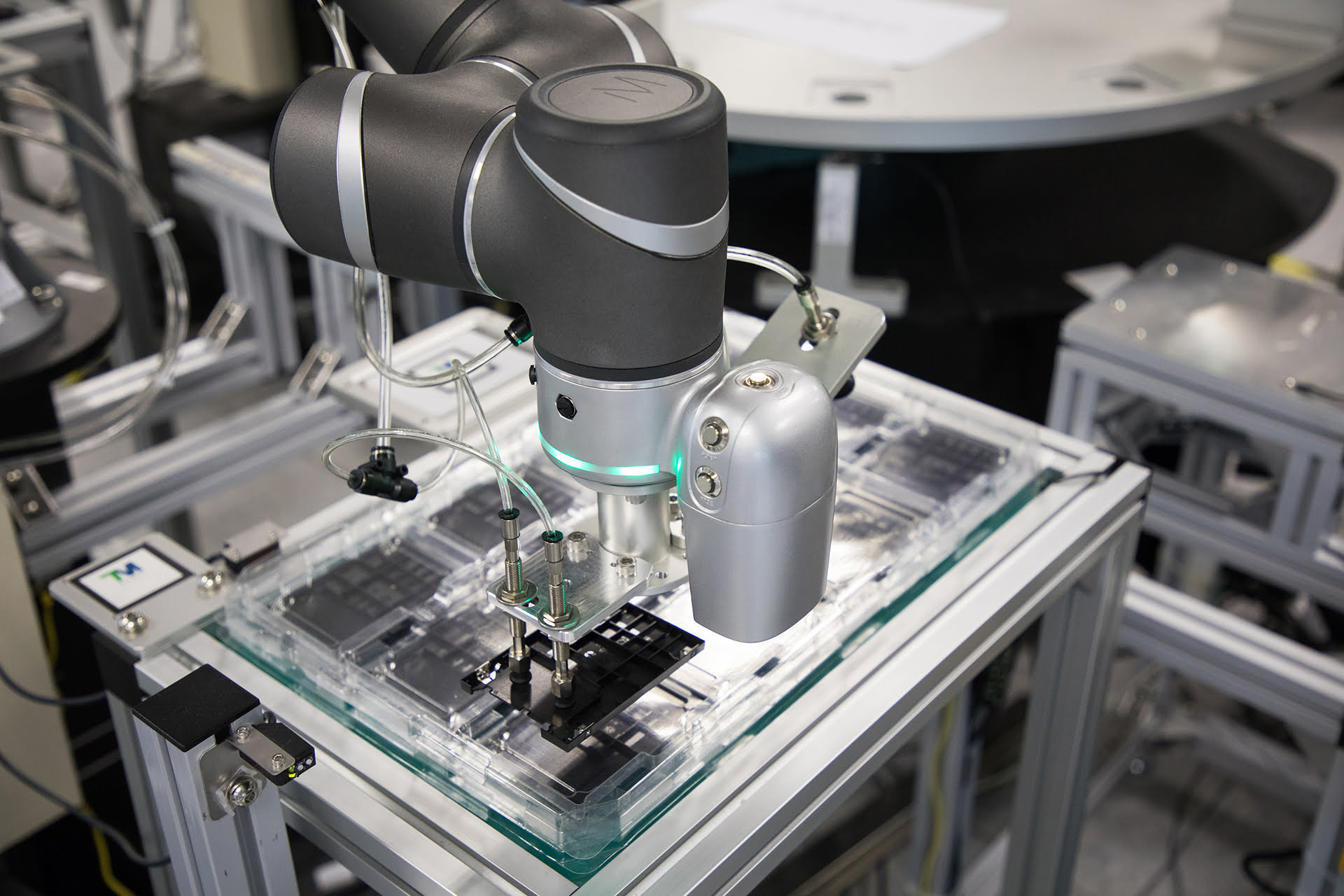

To remain profitable and competitive in 2024, increasing productivity is essential. To achieve this, automation is a good solution. Yet, many companies do not currently have the financial resources to automate and purchase industrial robots on a large scale. Cobots can be a solution to this. They are lighter, do not require too much expertise and are cheaper to purchase.

In many companies, people still do the so-called "dull, dirty and dangerous" work. Examples include palletizing where workers have to manually stack goods or boxes on pallets. These types of tasks lead to physical and mental problems for workers. Not only because it is heavy work, but also because it is mind-numbing and boring. Cobots or robots could take on these tasks, reducing the risk of injury and improving the quality of work. With minimal human effort, cobots can help bridge the labor shortage and allow employees to perform more valuable tasks. This not only increases productivity but also improves job satisfaction and reduces employee turnover.

Flexibility and competitive advantage

Consumer behavior is increasingly unpredictable, which also makes the production landscape increasingly unpredictable. Cobots offer flexibility to adapt to changing conditions, such as scaling up or down production. Automation is therefore becoming essential for manufacturers who want to remain competitive in this changing environment. In addition, automation can ensure that plant downtime is reduced. Cobots can perform tasks without rest and 24/7. This results in a significant improvement in productivity and the ability to run longer shifts.

Overcoming misconceptions

Although cobots are widely available, many companies have not yet considered them as a viable option. Capital costs and lack of in-house knowledge and experience often prove to be obstacles. However, it has been proven that cobots can achieve a return on investment (ROI) in as little as 12 months.

A common misconception is that cobots are difficult to implement or use. Modern cobots are designed with an accessible user interface, so employees do not need specialized expertise. The fear of automation and job loss to robots is also addressed: cobots are designed to work with humans, not replace them.

Cobot developments in 2024

What developments can we expect in collaborative robotics in 2024?

1. Sophisticated artificial intelligence (AI).

One of the most striking trends for 2024 is the refinement of artificial intelligence that controls cobots. These robots will not only be able to perform repetitive tasks, but also to learn and adapt to new situations. This opens the door to a wider range of tasks that cobots can perform, making them even more versatile in the workplace.

2. Advanced sensory systems

Cobots are being equipped with better and more sophisticated sensory systems. This means improvements not only in perceiving the environment, but also in understanding it. Cobots will be able to cooperate more accurately and safely with humans, thanks to improved visionary and tactile capabilities.

Advances in the sensory systems of cobots mean that they can not only better perceive what is going on around them, but also understand it. This means they can interact more accurately and safely with humans, thanks to improved visual and tactile capabilities.

For example, enhanced visionary capabilities could mean that cobots are able to detect objects with greater precision, estimate distances better and even understand complex environments. This enables them to perform tasks with a higher level of precision and adaptability. In terms of tactile capabilities, this refers to advanced tactile sensors that allow cobots to make physical contact with objects and understand the forces and pressures being applied. This not only improves safety when working with humans, but also opens the door to a wider range of tasks and applications that require more sensitive interaction with the environment.

3. Expansion of application areas

While cobots were initially introduced in production lines, in the future we will see a significant expansion of their application areas. From healthcare to retail, cobots will enter sectors where human collaboration is invaluable. This not only opens up new opportunities, but also contributes to a more efficient and flexible work environment.

4. Safety and human cooperation

A crucial aspect of developments in 2024 is the continued focus on safety and human cooperation. Cobots will become even better at anticipating human movement, minimizing the risk of accidents. This trust in collaboration will increase the acceptance of cobots in the workplace.

5. Training and implementation

With the increasing capabilities of cobots, the emphasis will be on effective training and implementation. Companies will invest in training to familiarize employees with the new generation of cobots. This will not only help in smooth integration, but also in harnessing the full potential of these technological advances.

Conclusion

In 2024, automation with collaborative robots, or cobots, appears to be an indispensable asset for manufacturing companies seeking to thrive amid economic uncertainties. The focus on increasing productivity and bridging workforce shortages makes cobots attractive, especially given their flexibility and safe collaboration with humans. While financial obstacles and misconceptions about implementation have yet to be overcome, expected developments in 2024, such as sophisticated artificial intelligence, advanced sensors, expansion of application areas and improved safety, promise a promising future for the manufacturing industry. It is clear that investing in training and implementation will be essential to harness the full potential of cobots to maintain a sustainable competitive advantage.

WiredWorkers is an expert in the field of automation and has already helped several companies implement collaborative robots. Contact us or schedule a free cobot consultation!