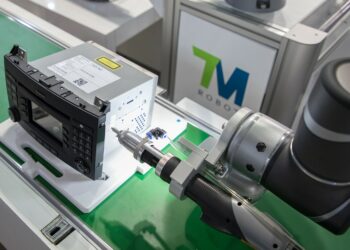

Pick and place with a collaborative robot

Many applications of a cobot are a variant of pick and place. Picking up objects and then offering them again in a different place is the basis of an automation project. Think about machine loading, palletizing, packing and testing. For all these applications, it is important that the cobot picks up an object in order to offer it to a machine or to sort it. The biggest challenge in implementing a pick and place task is the supply of the products. The easiest way is to have a structured supply, so that a cobot knows where the product is and can always move to the same place to pick it up. This is not always possible, for example because the products are delivered in bulk, but also if the products differ in shape and/or size. In that case the application becomes more complex and robot vision and bin picking can be a solution.

Cobot pick and place benefits

-

Saving of costs

You will save on personnel costs

-

Increasing productivity

Staff can do other work

-

Utilize full capacity

Get more out of your employees

-

Prevent disorders

Prevent disorders among employees

-

No loss of concentration

Robots will never lose concentration

-

Constant quality of output

Robots deliver consitent quality

Empower your staff

A simple pick and place task, such as loading a CNC machine or stacking boxes is a boring, repetitive task for people. Performing this in a concentrated manner day in and day out takes a lot out of the workforce. In addition, lifting or repeating the same movements can cause complaints over time. Automating this type of work allows staff to do other work where they are more challenged, less likely to be injured and ultimately happier in the work they do. In addition, it contributes to productivity.

Other applications

- « Previous

- 1

- 2

- 3

- Next »