What is cobotics?

Cobotics (cobots or collaborative robots) is a new application in industrial automation. These robots are equipped with sensors that give robots "feel. This means that they can do very delicate work and cooperate with people. As soon as they sense that their work is being interfered with, they stop immediately. Therefore, it is safe for workers to work near a cobot. Other advantages of cobotics are that it is a compact, mobile solution. These robots can operate in different places in a company and new tasks are learned in no time. The installation and programming process is very user-friendly and simple.

Different cobotics brands

There are many different types of cobots on the market. Each robot has its own unique characteristics. This combined with tooling makes the possibilities for automation endless. The most common brands of cobotics are Franka Emika, Universal Robots and Techman Robot.

Franka Emika

Germany's Franka Emika has focused her Production 3 on a cobot that mimics the human arm as much as possible. This robot is equipped with more than 100 different kinds of sensors to give the cobot as much "feel" as possible. In addition, a great deal of emphasis was placed on dexterity in the design of the joints. This makes it very suitable for very delicate tasks.

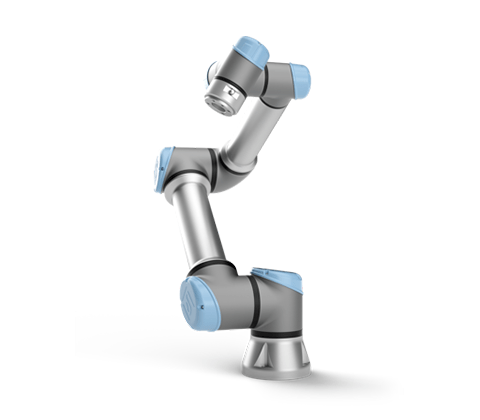

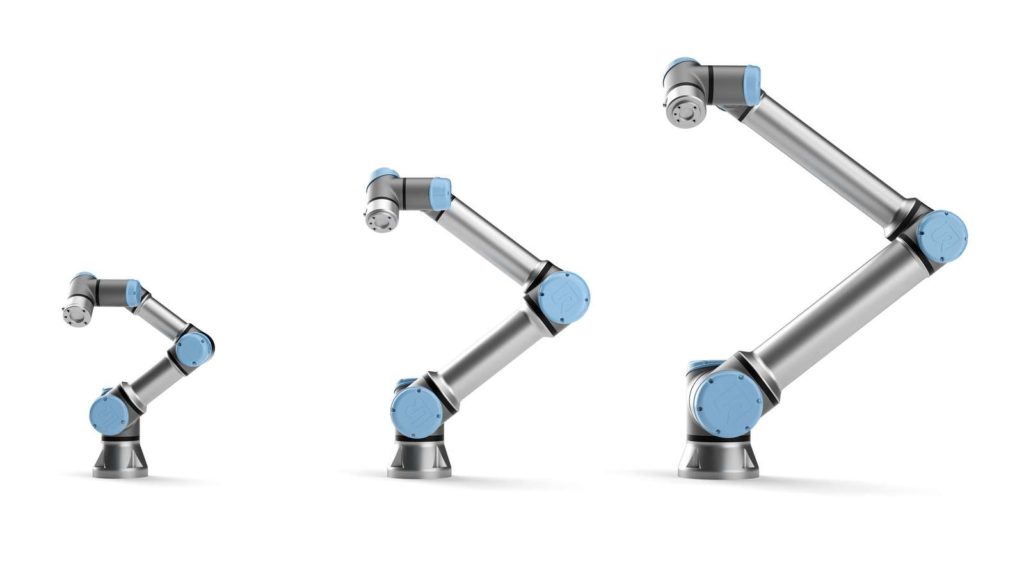

Universal Robots

Universal Robots is the largest cobot brand in the world and offers many different robots made for heavier work. The fact that this manufacturer is so large means that by far most tools are also compatible with the robots. The UR3, UR5, UR10, UR16 and UR20 all have different ranges and payloads. So whatever there is to automate, there is always a UR that can do it.

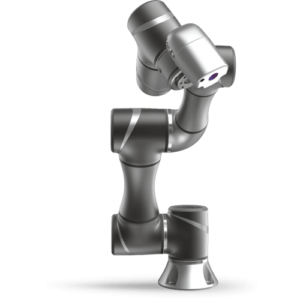

Techman Robot

Techman Robot is the first robot with integrated vision. The advantage of this over other systems, is that in both the hardware and the software the vision system is integrated. This makes setting up a vision related task extremely user friendly. In addition, these robots are super accurate. The repeatability of the robot arm is 0.5 mm.

Cobotics applications and tooling

There are many different applications for which a cobot can be used. Thanks to the combination of the easy-to-program software and many different tooling, a cobot can be taught almost anything.

Grippers

For cobotics, there are several types of grippers on the market. Consider simple finger grippers, vacuum grippers, magnetic grippers, and so on. Grippers are naturally used to move objects. For example for stacking a pallet, loading products into a machine or putting products on a conveyor belt.

End of arm tooling

End of arm tooling (EOAT) are different types of tools within cobotics that can be made at the end of the robotic arm. These can be glue dispensers, screw machines, sanders, sensors or welding and soldering irons. More and more companies have started to focus on developing this type of tooling in recent years, so the possibilities for cobotics are thus increasing.

Vision

Vision systems allow a cobot to see. With 2D or 3D cameras, a cobot can locate objects, recognize patterns, scan barcodes and much more. The advantage of vision is that the supply of products does not necessarily have to be structured because the robot can see where the products are. In addition, a robot could also perform optical inspection with vision.

WiredWorkers | Cobotics company

WiredWorkers is a cobotics company that offers various services in the field of collaborative robots. We can help automate total applications, building the complete machines and implementing the robot. We also offer feasibility studies, to see in advance if automation is a viable, profitable option. We also rent cobots to companies that want to explore the possibilities of collaborative automation. After an implementation process, we offer training to teach employees how to handle and program the robot. Curious about the possibilities? Get in touch with us!