Robot automation with cobots

Cobots represents a cutting-edge technology in the realm of robot automation, setting it apart from traditional automation alternatives. The key distinction lies in the remarkable sensitivity exhibited by cobots. Equipped with advanced sensors, cobots possess a heightened awareness of their surroundings and can interact safely with humans. Their ability to detect and respond to obstacles enables them to halt operations promptly, minimizing the risk of accidents.

Furthermore, cobots offer a significant advantage in terms of programming. Unlike traditional robots, which necessitate substantial time and expertise for programming, cobots can be swiftly programmed using user-friendly software or mobile apps. This streamlined programming process empowers users to configure cobots efficiently, saving valuable time and eliminating the need for extensive technical knowledge.

Moreover, collaborative robots exhibit remarkable versatility, effortlessly adapting to diverse tasks. Their mobility grants them exceptional flexibility, making them an ideal solution for production companies characterized by low volumes and substantial variation in the production line.

Experience the transformative potential of robot automation for your organization. Contact us now to learn more about how cobots can revolutionize your operations.

The many possibilities of robot automation with cobots

The remarkable flexibility and mobility of cobots open up a wide range of possibilities for task execution. A cobot can be assigned to perform a specific task over an extended period, or it can engage in different activities on a daily basis. For instance, by placing the cobot on a mobile workstation, it becomes effortless to switch between various tasks. The intuitive and user-friendly software enables quick and easy programming for new assignments, making cobots an ideal tool for enhancing production during busy periods.

With a plethora of tools available in the market, cobots can adeptly learn and execute almost any repetitive action. Tasks such as gluing, sanding, welding, soldering, screwing, machine loading, palletizing, and many more can be efficiently performed by cobots. Embrace the versatility of robot automation and explore how it can revolutionize your production processes

Different brands of cobots

There are different types of cobots on the market. Each brand has its own unique characteristics that also make them suitable for different applications. WiredWorkers works with three brands; Franka Emika, Universal Robots and Techman Robot.

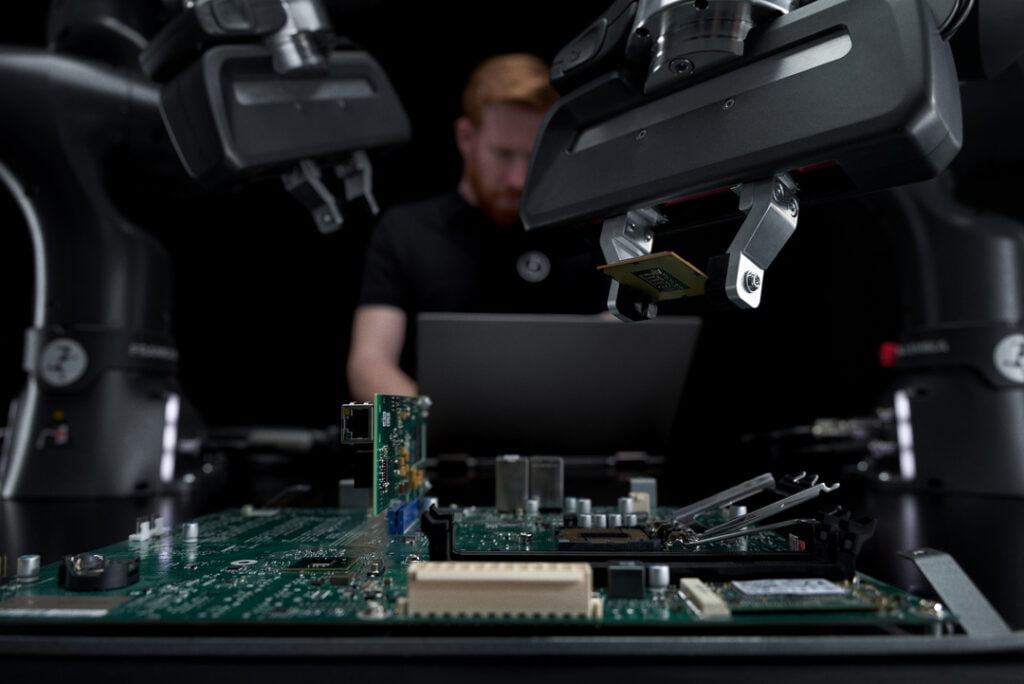

Franka Emika

One of the most advanced cobot systems is the Production 3 from German manufacturer Franka Emika. It is a compact, sensitive, flexible robot designed to work like a human arm. With its 7 joints, all equipped with sensors, the cobot can perform the most sophisticated actions. The Production 3 has a range of 850 millimeters and is able to move objects up to 3 kilograms.

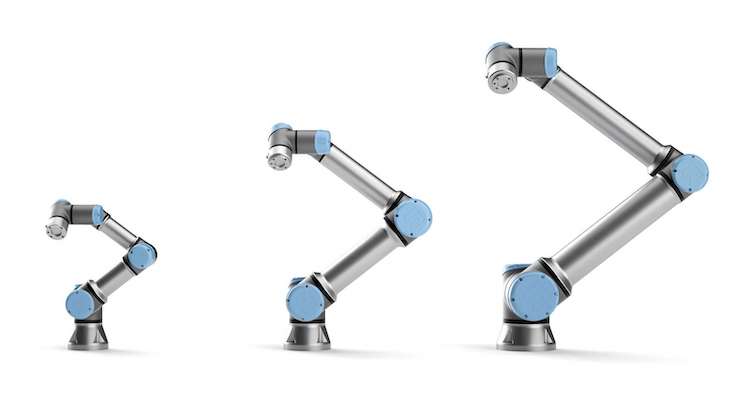

Universal Robots

Universal Robots are robust cobots made for heavier work. With the UR3, UR5, UR10 and UR16, Universal Robots has a wide range of cobots with variable payloads and ranges. With that, they offer a suitable solution for every challenge.

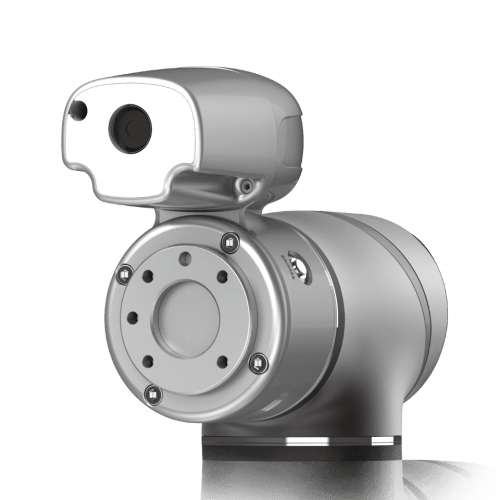

Techman Robot

Techman's collaborative robots are the first cobots on the market with integrated vision. Both hardware and software systems are integrated, as well as various standard robot vision functions. Think pattern matching, object localization, barcode scanning and color recognition. Thanks to the user-friendly user interface, it is accessible to everyone to use this cobot.

In addition to the integrated vision functions, Techman Robot's robots are characterized by a particularly high degree of accuracy. The robots are accurate to within 0.5 mm, making them suitable for the most sensitive tasks.

WiredWorkers, robot automation specialist.

WiredWorkers specializes in comprehensive robot automation solutions, offering end-to-end assistance to companies throughout the "cobotization" process. Starting with a detailed analysis of business processes, we identify bottlenecks and determine optimal areas where cobots can deliver maximum efficiency. We prioritize building trust and facilitating seamless collaboration between employees and their robot colleagues, which is why we provide thorough cobot training.

Additionally, we offer the option to rent cobots, allowing for the deployment of temporary robotic employees. This is an ideal solution for boosting production capacity during busy periods and peak times, ensuring optimal performance and flexibility. If you would like more information about the possibilities and benefits of robot automation, please don't hesitate to contact us. Our team is ready to provide you with the insights and support you need to transform your operations.