The logistics sector is booming! Partly due to the enormous increase in e-commerce, the demand within the logistics sector has grown enormously and this is only expected to increase in the coming period. To remain competitive within this sector, 'smart warehousing' is becoming increasingly important. The first thought of smart warehousing is often AGVs that drive pallets or carts around the warehouse. On the other hand, packaging products and packages is also a big part of logistics. How can cobots be of value in automating packaging processes?

Common challenges in logistics

Throughout the logistics sector, packaging processes have been undergoing changes for a while now, and mainly sustainability plays an important role in this. The use of packaging has to be done with as little waste as possible, environmentally friendly packaging materials and as much reuse as possible. In addition, the shortage of logistics personnel is another major challenge that could play a major role in the future. Collaborative robots could be a valuable tool to address these challenges.

Waste

The demand for more sustainable packaging has been rising for years and will only increase in the near future. 66% of consumers consider the sustainability of the packaging when choosing a product and 35% are willing to pay more for it. If a company decides to work more sustainably, packaging is a good place to start.

Productivity

According to various studies, absenteeism in the logistics sector is higher than average. Obviously, the productivity of the industry suffers from this. Part of the problem may lie in the heaviness of the work. If heavy lifting is often required, or if repetitive actions often have to be performed, this can lead to muscle and joint disorders. Robots could obviously prevent this if they take over the work of the operator (in part).

Labor shortage

The tremendous growth of the e-commerce sector is, of course, a triumph for the logistics industry. On the other hand, it has also caused a shortage of personnel. In addition, the logistics sector often works in shifts, during the day and at night. It is already difficult to find suitable personnel, for night shifts it is even more complicated. This problem stems from several factors, but robotization is one way to close this gap.

The role of robots within packaging processes

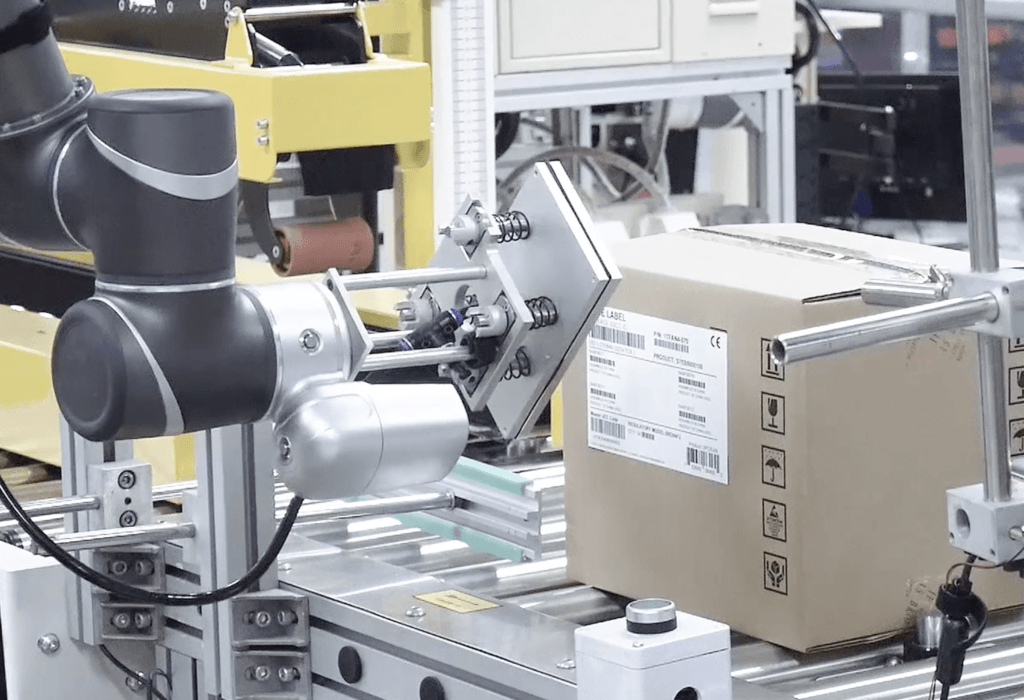

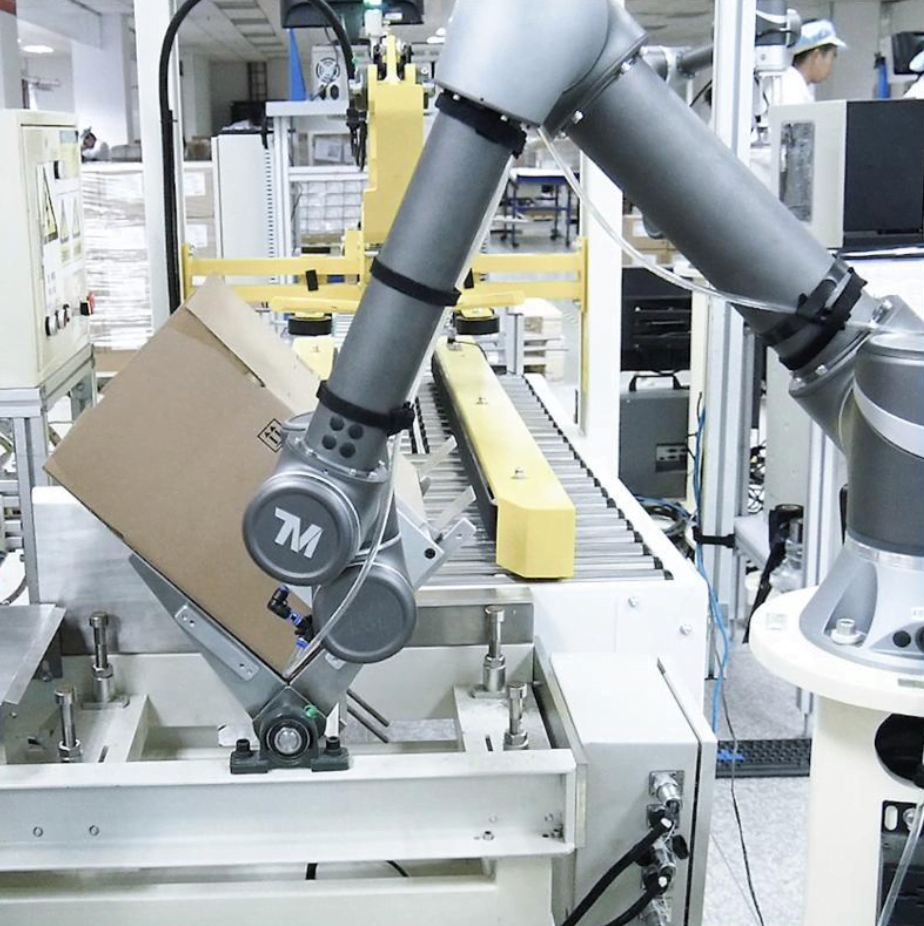

Packaging processes are often seen as human work. Until a few years ago, this was also the case. Packaging tasks were often too complex to automate because of the high degree of variability. The large and inflexible robots, which were traditionally used for automation, made this even more complex. Automation was really only profitable for very regular tasks with little variability. The advent of collaborative robots has changed this and made it possible to automate very flexible packaging processes.

There are two packaging applications that are best suited to automation:

Pick-and-place: This application means little more than picking up and moving a product. Perfect for picking up products or small boxes and putting them in boxes.

Palletizing: In this application, the cobot picks up boxes and puts them in a preset pattern on a pallet ready for transport.

Advantages of a robot in packaging processes

Collaborative robots add value to a packaging process in several ways. Here are 5 useful benefits:

Increased consistency

A robot will always perform a task in exactly the same way. Unlike a human, who loses concentration when faced with a boring, repetitive task and becomes sloppier as a result. Humans benefit more from a more creative, problem-solving task. A robot thus provides consistent quality that cannot be surpassed by a human employee.

Cost Savings

Because cobots are a relatively low-cost solution, the time in which it pays for itself is short. Once this point is reached, the labor costs of the packaging task drop. The money thus released can be spent on other things, such as making the packaging more sustainable.

Working 24/7

A robot does not need a break and can, in principle, work 24/7. In this respect, a human employee will never win from a robot. As demand continues to rise and the logistics sector never stands still, a robot can be a distinguishing factor for the competition.

Better use of space

Collaborative robots are compact, unlike the previous generation of industrial robots. Opting for a collaborative robot saves floor space, making companies more sustainable overall.

Flexibility

Demand within the logistics industry can fluctuate tremendously. Especially if you look at e-commerce, for example, there is a huge increase in the number of packages sent around the holidays, but manufacturing companies also have to deal with peaks in production from time to time. This is where a collaborative robot can come in handy. Thanks to simple software, it is easy to reprogram. In this way, the robot can be used wherever it is needed at the time and does not have to perform the same task 24/7.

Getting Started!

WiredWorkers specializes in automation and can help you make the right choices. For example, we offer the Cobot Palletizer, a complete plug-and-play palletizing robot designed specifically for automating palletizing. We can also help with other packaging applications such as pick-and-place or boxes-into-box applications. Contact us or schedule a free cobot consultation.