Palletizing with a collaborative robot

Palletizing is the placing of products or boxes on a pallet that is being prepared for shipping or storage. This task can be perfectly automated using a cobot. The cobot can stack the products in a desired pattern, maximizing the amount of cargo and reducing the chance of toppling over. Today, many pallets are still stacked manually. A simple, tedious task, which can lead to physical complaints if there is a lot of weight. A cobot, provided the goods are delivered constantly, can keep stacking endlessly. When production continues 24 hours a day, robots can reduce the cycle time of a stacked pallet.

Cobot palletizing benefits

-

Saving of costs

You will save on personnel costs

-

Increasing productivity

Staff can do other work

-

Utilize full capacity

Get more out of your employees

-

Prevent disorders

Prevent disorders among employees

-

No loss of concentration

Robots will never lose concentration

-

Constant quality of output

Robots deliver consitent quality

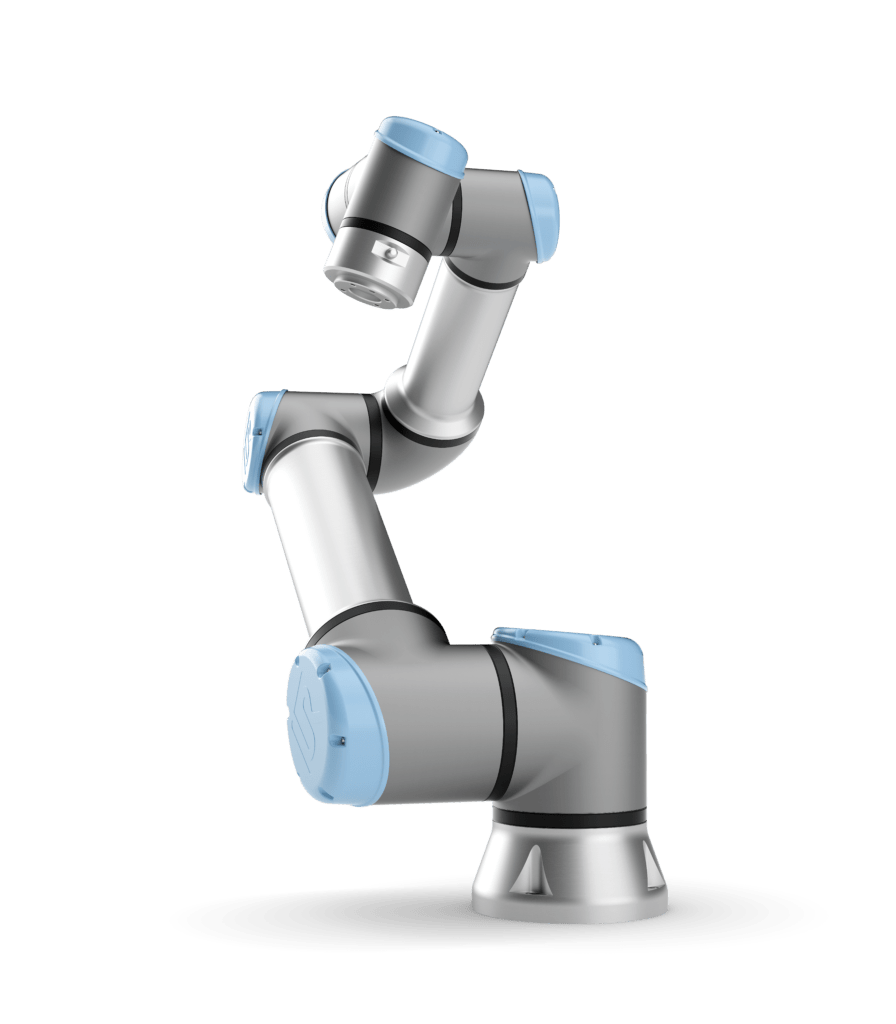

Specially designed solution

The cobot palletizer is an in-house developed solution designed for seamless integration into your packaging line. Its standardized design ensures fast deployment with minimal modifications, and its mobility allows it to be used across different locations. With intuitive software, configuring new pallet patterns is quick and straightforward, making it an efficient and flexible option for various applications.

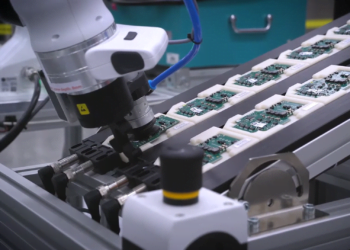

Cobot palletizing video

Check out the video below in which a cobot palletizing solution is demonstrated.