Collaborative robots in the electronics industry

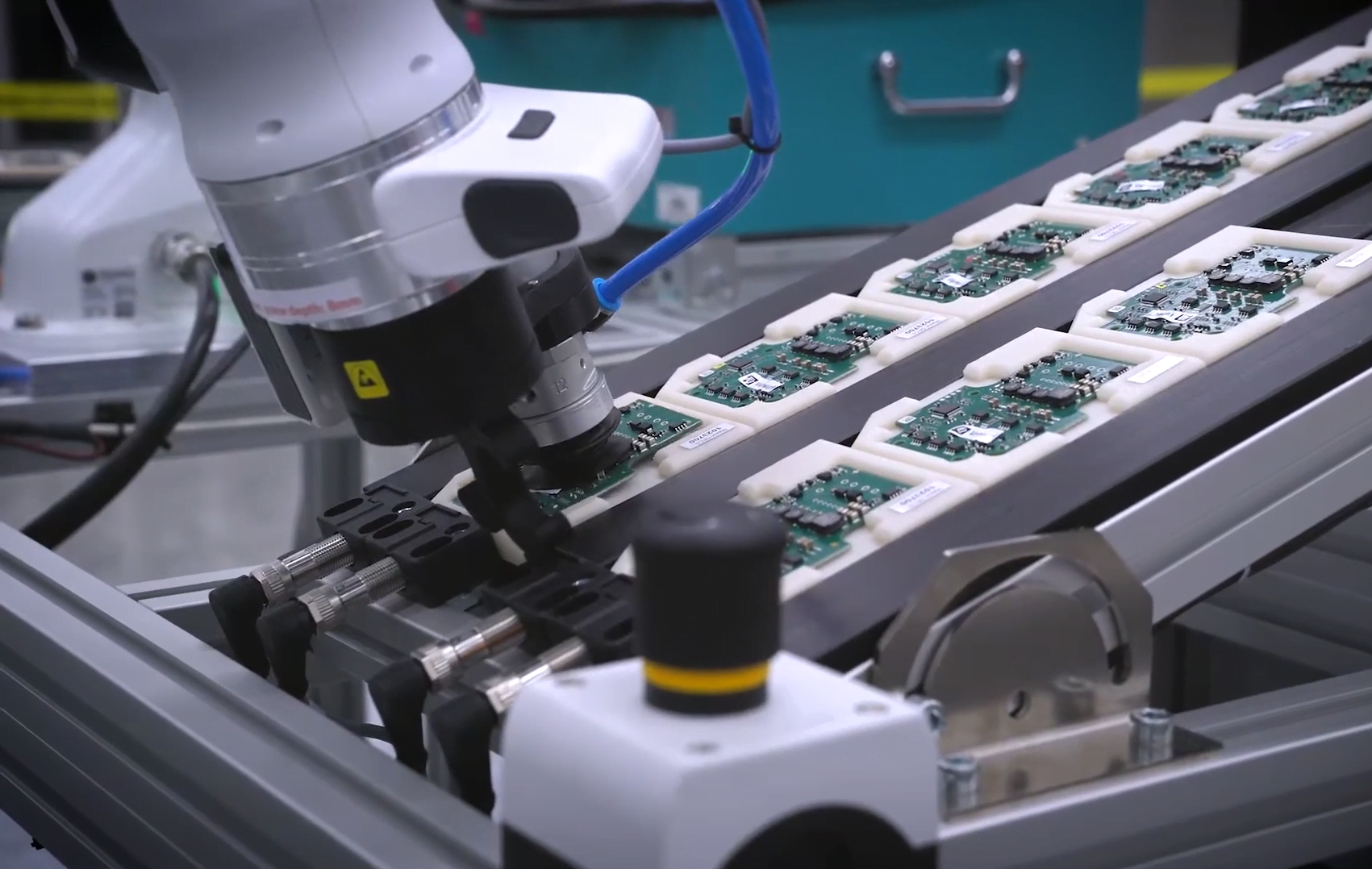

Within the electronics industry, product testing and quality control are the most common tasks automated by a cobot. A cobot can insert chips into testing machines and then sort them. In addition, a cobot is also perfect for soldering PCBs. Because a cobot is so precise and can work very delicately thanks to built-in sensors, a cobot is perfect for these kinds of fragile products. This reduces the margin of error and makes the entire production process more efficient and productive.

Advantages of cobots in the electronics industry

In the electronics industry, cobots offer significant benefits by augmenting human labor and enhancing productivity and efficiency in production processes. By leveraging cobots, companies can accelerate their manufacturing processes, boost production capacity, and uphold product quality standards. Moreover, cobots can significantly enhance worker safety by assuming hazardous and monotonous tasks, freeing up human labor for more complex operations.

Cobot applications for the food industry

-

Chip Testing

Handling the smallest and most delicate chips requires the use of vacuum suction and subsequent delicate insertion into the testing machine. Cobots are designed and developed to meet these specific challenges.

-

Touchscreen device testing

Perform a reliable end-of-line quality control procedure to test any type of touch screen with a collaborative robot.

-

Soldering

By mounting special end-of-arm tooling at the end of the cobot, the robot can perform various soldering processes, including soldering PCBs.