Labelling of crates

Egg traceability is twofold. In most countries, eggs are coded with the farm of origin. This allows consumers to see where the egg was produced. Conversely, it is also necessary for sellers to know which eggs from a particular producer, farm and laying date have been sent to the customer, in case products need to be recalled. In doing so, sellers do not want to rely on the code on the egg, but it is easier to tell the customer which pallet or crates they need to send back.

Therefore, containers with chick boxes need a unique barcode that indicates the origin of the day-old chicks. Hatchtrack offers a solution for this. Farm labels are printed for each breeder in which data are recorded. It can be used stand-alone, but can also be linked to an ERP or invoicing system.

Labelling those crates is a monotonous, manual task that was performed by employees. To relieve employees of this boring, mind-numbing task, it was decided to automate this operation with a collaborative robot. This way, employees had their hands free for more challenging tasks.

Automated labelling machine

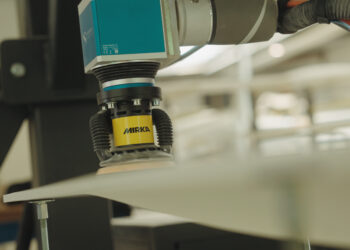

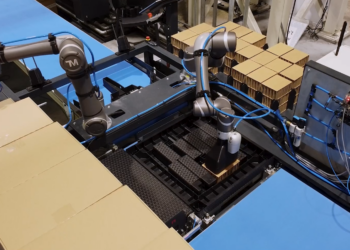

To automate the labelling of the crates, WiredWorkers developed an automated labelling machine using Techman Robot's TM5-900. The robot is placed in the centre of the set-up and buffers are made on both sides of the robot where the crates are stacked. Next to the robot is a label dispenser from which the robot picks up labels using vacuum and a custom-made gripper. The robot then moves to the crate and places the label on the designated spot. This process repeats itself until the stack is ready, after which the robot continues with the other stack. When a stack is ready, a light comes on, allowing an operator to change the stack.

If other types of crates need to be turned, the robot programme can be easily adjusted in the HMI thanks to the user-friendly software. Watch the video of the labelling process below.

Increased productivity and employee satisfaction

Thanks to the deployment of the automated label machine, the productivity of the department has increased. Employees who in the past were busy sticking labels have their hands free to be busy with other tasks. In addition, employees are relieved of this boring, mind-numbing task, challenging them to perform more complex tasks such as quality control. This ultimately leads to greater employee satisfaction and a contributes to employee well-being.