Collaborative robots in the plastics industry

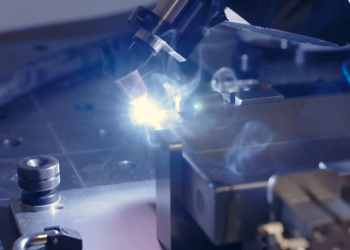

Within the plastics industry, injection molding is one of the most common tasks where a cobot can help. For example, a cobot could be used to unload the injection molding machine. It could also be used to change mold parts or for post-processing of products, such as polishing or coating. Further down the production process, a cobot can also be of value. For example, in inspecting and sorting products, or in quality inspection. Other repetitive actions such as drilling, screwing and gluing are also tasks that can be automated with a cobot.

Cobot applications for the plastics industry

-

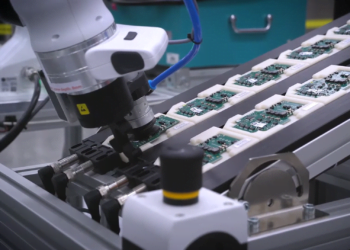

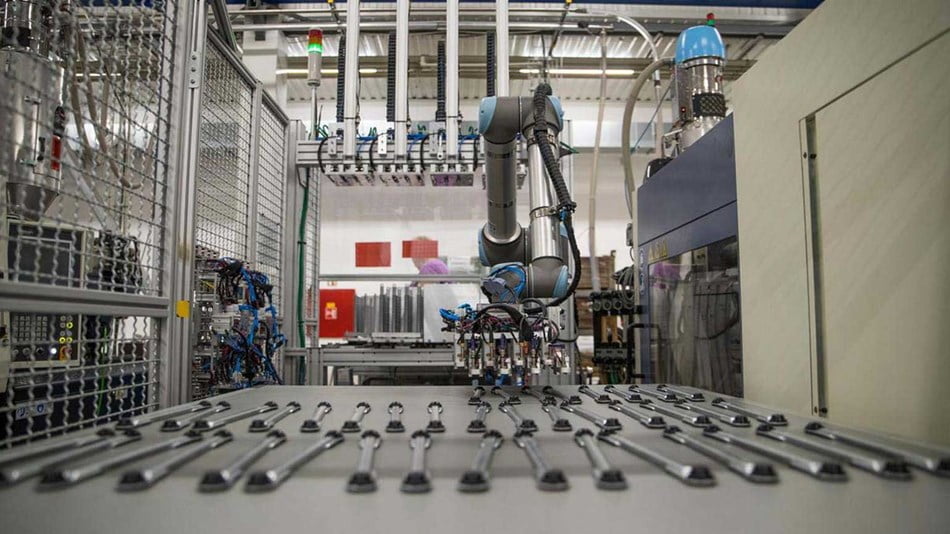

Machine tending

Machine tending is the placement of parts in, for example, a CNC lathe, bending machine, injection molding machine or 3D printer.

-

Palletizing

Palletizing can be simpler, faster and more efficiently with a cobot. By automating palletizing of your products, you lighten the work of your employees.

-

Pick-and-place

Pick-and-place means little more than picking up and moving a product. Perfect for picking up products or small boxes and putting them in boxes.

-

Logistical automation

Other industries...

- « Previous

- 1

- 2