Collaborative robots in the FMCG industry

Until recently, the FMCG industry could only marginally leverage robotization, largely due to product variety, fast-changing demand, and strict quality standards—challenges that traditional robots struggled to meet. However, the rapid evolution of cobots is changing the game. The integration of advanced gripper technology with vision systems has sparked a major shift, enabling cobots to handle delicate, irregularly shaped, or varied products with unprecedented precision and care

Key benefits of cobots in the FMCG industry.

-

Productivity & efficiency

Cobots accelerate processing and packaging tasks, increasing output without compromising consistency.

-

Safety & Quality

By taking over repetitive or potentially hazardous tasks, cobots reduce the risk of accidents and improve food and product safety.

-

Flexibility & Adaptability

Cobots can be reprogrammed and reused – ideal for fluctuating product ranges or seasonal peaks.

-

Plug & Produce

Standardized cobot solutions can be deployed quickly, minimizing implementation time and costs.

Cobot applications for the FMCG industry

-

Palletizing

Palletizing can be simpler, faster and more efficiently with a cobot. By automating palletizing of your products, you lighten the work of your employees.

-

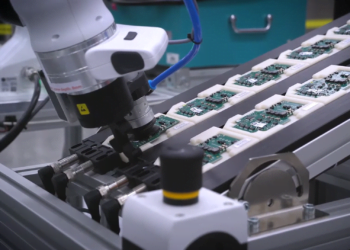

Pick-and-place

Pick-and-place means little more than picking up and moving a product. Perfect for picking up products or small boxes and putting them in boxes.

-

Quality inspection

Cobots can play a crucial role in quality control and product inspection. Equipped with advanced vision tools, cobots are able to detect defects, check dimensions, verify labels, and monitor product consistency in real time.

Our quality principles...

-

Integration from start to finish

-

Multidisciplinary team

-

Brand independent

-

Transparent working procedure

-

Closely involved

Other industries...

- « Previous

- 1

- 2

- 3

- Next »